Charles (Upstate NY)

Well-known member

@Odanscoils commented that he would like to know how to build a concentric coaxial/coplanar coil for his Minelab Explorer. I'm starting this thread to discuss.

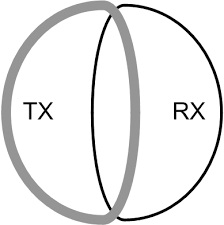

If you take an Explorer DD coil apart you will find two windings of copper magnet wire. A thicker heavier gauge wire TX (transmit) winding, and a thinner smaller gauge wire RX (receive) winding. Both the rough shape of a "D", a D and a backwards D, with the windings overlapping down the center.

Explorers require balanced coils - So what does that mean? The TX transmit winding is blasting out a powerful transmit signal, this is what induces a signal into the target. Naturally we can't have the transmit signal being picked up by the RX receive winding that would drown out targets. The RX winding 'detects' the tiny induced signal back from the target. It turns out though if you overlap the TX and RX windings precisely, monitoring RX on an oscilloscope you can 'balance' the windings. Watching the RX winding on the scope as you adjust the overlap you can watch the TX signal that's riding on the RX winding shrink then flatline, the coil is then balanced. This is touchy, a little nudge one way or another can knock the coil out of balance e.g. you can see some TX signal on the RX winding. Just the epoxy setting up can pull the coil out of balance. I began testing new coils I purchased and found maybe 1 out of 4-5 coils was actually out of balance from the factory.

Concentric coils must also be balanced, there are different methods. This one uses a variation on the DD above, overlapping the TX and RX windings.

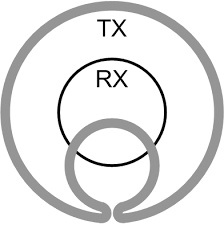

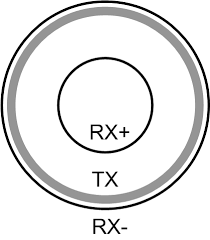

This approach introduces the Bucking Coil to balance e.g. reduce the TX signal riding on the RX winding to zero. Here you see a single TX winding, inner RX winding, and outer RX winding in the opposite direction of the inner RX e.g. bucking. It's the number of bucking coil winds that gets you to balance. This can be a partial wind or turn, it's that sensitive.

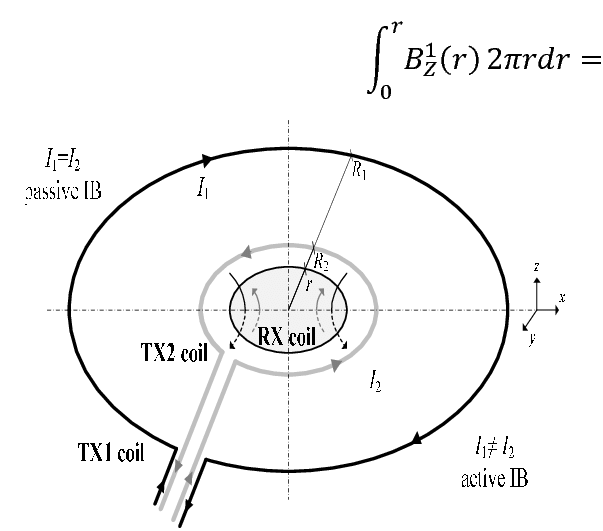

Here the opposite method is used, ignore the math. Here an outer TX1 winding, inner TX2 winding (the bucking coil to balance the coil) wired in the opposite or reverse direction as TX1, and the inner RX winding.

I'm going to stop here with some info. So far this looks pretty simple. Just some windings of copper magnet wire. No chips or electronics in the coil. But before you step into building your own coil know this, the devil is in the details. It's not nearly as simple as it seems. It's not impossible but not this simple. If you measure a sample of Minelab/After Market coils for the Explorer you will find they are all built to very tight tolerances. Resistance, Impedance, Inductance, Capacitance, and Q are all within a very narrow tolerance range that your coil must match. Some are in a tug-of-war with each other. Number of winds to hit the Inductance may over/under hit the resistance tolerance. Different gauge wires required for different sized windings e.g. coils. How tight or loose the windings are wound. The type and thickness of the insulation on the copper magnet wire. Minelab uses Litz wire for the TX winding that's a whole other discussion.

This ^^^ is before we even discuss assembling the coil. Some tricky things specific to the concentric coil, where the bucking coil wire exits. You literally will be winding that bucking coil and have to stop at say 9 o-clock where the coil is in perfect balance, but what if your exist for that wire in the coil shell is at 3 o-clock on the opposite side of the coil shell, see tricky. The entire coil assembly TX/RX/TX for example must be encased in a shielded cocoon tied back to the detector's ground. This brings into play how to do that. The shielding cannot come into contact with the outside world, it must be electrically insulated by the outer coil shell. Drain wires. You will use carbon black shielding paint, it's just conductive enough without being too conductive. The Eplorer can actually detect nickel based shielding paint for example. Coming back to balancing the coil, the epoxy during the cure can pull your coil out of balance during the curing process, so how to deal with that. Assembling has it's own set of challenges.

That said it was great fun building coils, even when the process became maddening.

If you take an Explorer DD coil apart you will find two windings of copper magnet wire. A thicker heavier gauge wire TX (transmit) winding, and a thinner smaller gauge wire RX (receive) winding. Both the rough shape of a "D", a D and a backwards D, with the windings overlapping down the center.

Explorers require balanced coils - So what does that mean? The TX transmit winding is blasting out a powerful transmit signal, this is what induces a signal into the target. Naturally we can't have the transmit signal being picked up by the RX receive winding that would drown out targets. The RX winding 'detects' the tiny induced signal back from the target. It turns out though if you overlap the TX and RX windings precisely, monitoring RX on an oscilloscope you can 'balance' the windings. Watching the RX winding on the scope as you adjust the overlap you can watch the TX signal that's riding on the RX winding shrink then flatline, the coil is then balanced. This is touchy, a little nudge one way or another can knock the coil out of balance e.g. you can see some TX signal on the RX winding. Just the epoxy setting up can pull the coil out of balance. I began testing new coils I purchased and found maybe 1 out of 4-5 coils was actually out of balance from the factory.

Concentric coils must also be balanced, there are different methods. This one uses a variation on the DD above, overlapping the TX and RX windings.

This approach introduces the Bucking Coil to balance e.g. reduce the TX signal riding on the RX winding to zero. Here you see a single TX winding, inner RX winding, and outer RX winding in the opposite direction of the inner RX e.g. bucking. It's the number of bucking coil winds that gets you to balance. This can be a partial wind or turn, it's that sensitive.

Here the opposite method is used, ignore the math. Here an outer TX1 winding, inner TX2 winding (the bucking coil to balance the coil) wired in the opposite or reverse direction as TX1, and the inner RX winding.

I'm going to stop here with some info. So far this looks pretty simple. Just some windings of copper magnet wire. No chips or electronics in the coil. But before you step into building your own coil know this, the devil is in the details. It's not nearly as simple as it seems. It's not impossible but not this simple. If you measure a sample of Minelab/After Market coils for the Explorer you will find they are all built to very tight tolerances. Resistance, Impedance, Inductance, Capacitance, and Q are all within a very narrow tolerance range that your coil must match. Some are in a tug-of-war with each other. Number of winds to hit the Inductance may over/under hit the resistance tolerance. Different gauge wires required for different sized windings e.g. coils. How tight or loose the windings are wound. The type and thickness of the insulation on the copper magnet wire. Minelab uses Litz wire for the TX winding that's a whole other discussion.

This ^^^ is before we even discuss assembling the coil. Some tricky things specific to the concentric coil, where the bucking coil wire exits. You literally will be winding that bucking coil and have to stop at say 9 o-clock where the coil is in perfect balance, but what if your exist for that wire in the coil shell is at 3 o-clock on the opposite side of the coil shell, see tricky. The entire coil assembly TX/RX/TX for example must be encased in a shielded cocoon tied back to the detector's ground. This brings into play how to do that. The shielding cannot come into contact with the outside world, it must be electrically insulated by the outer coil shell. Drain wires. You will use carbon black shielding paint, it's just conductive enough without being too conductive. The Eplorer can actually detect nickel based shielding paint for example. Coming back to balancing the coil, the epoxy during the cure can pull your coil out of balance during the curing process, so how to deal with that. Assembling has it's own set of challenges.

That said it was great fun building coils, even when the process became maddening.