Seems to rain every weekend here in NY. Been caught out there several times... but I got tired of tying a ShopRite bag over my Ace 250. Looks so ghetto, and it's difficult to work through.

So I decided to make it water resistant.

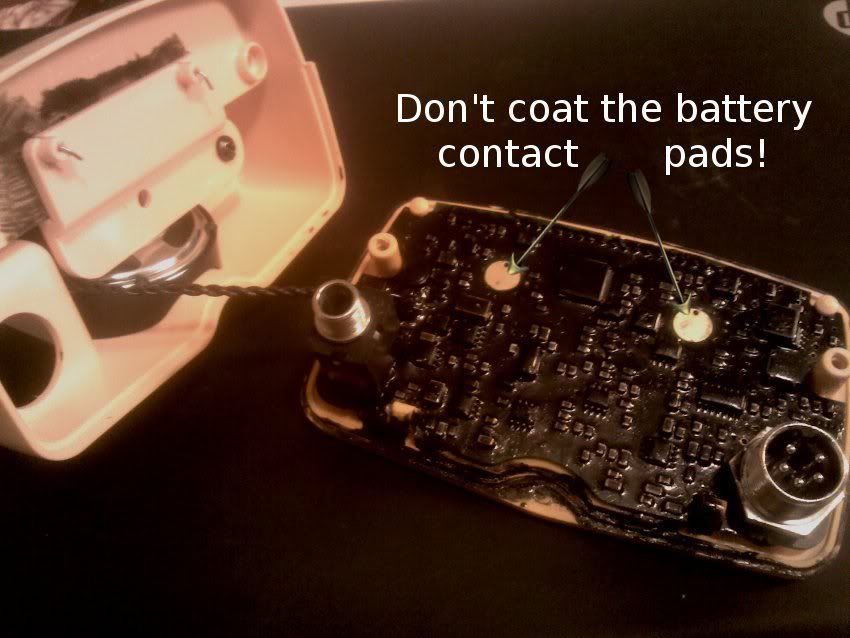

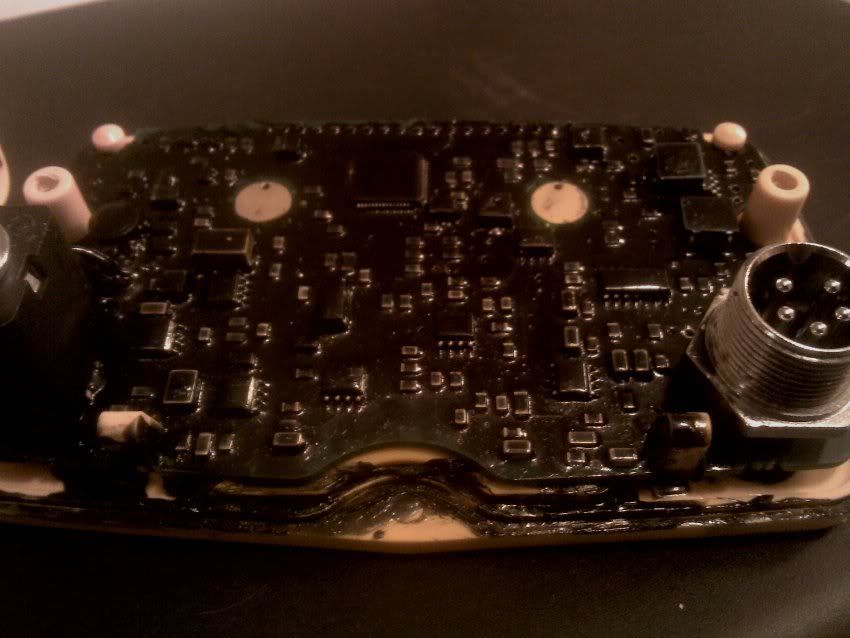

I disassembled the control box, separated the circuit board, and laid it on a paper plate. I put a liberal coating of Permatex liquid electrical tape on the component side of the board, being careful not to get any on the two big battery contacts. On the other side I coated the little through-holes and the solder sides of the coil connector and headphone jack. Then I lifted the display from the board just enough to brush the tape under it because there are through-holes there too. The display leads got a decent coating because I wanted the tape to flow around each lead sealing all sides.

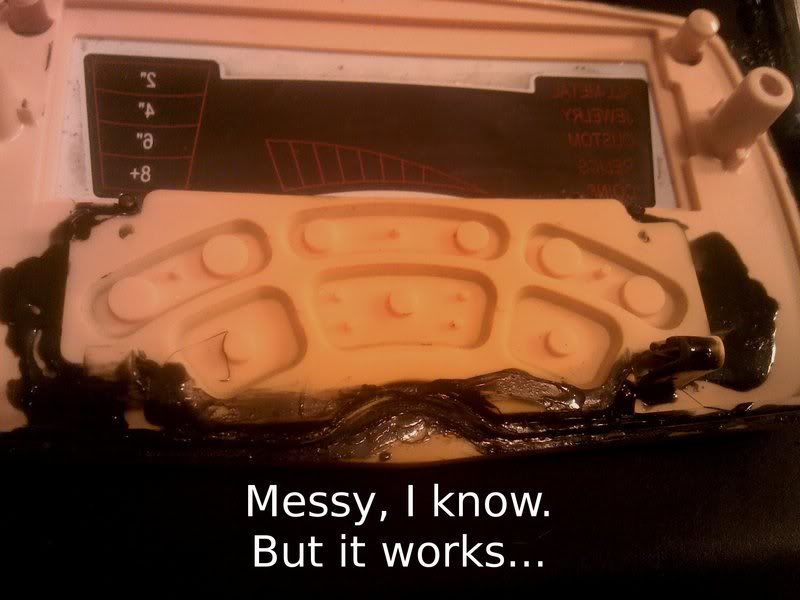

Next I coated the areas around the button pads on the faceplate. Just enough to make a seal. Then I used a toothpick to dab and drag some of the tape around the entire faceplate. That sorta made a gasket.

Now the hard part....

I waited the FULL 4 HOURS FOR THE LIQUID TAPE TO DRY before reassembling and powering it up. Then I reassembled the box, mounted it on the stick, connected the coil, crossed my fingers and hit 'Power'.

It works! I air-tested it with my wedding ring, a silver dime, foil, and a nail. Wotks perfect. *WHEW*

I read that some people ran into problems with their circuitry skitzing out when using liquid tape but I think they may have powered it up while the tape was still partially liquid.

Long story short, I took a gamble, voided my warranty, and got lucky.

The warranty may still be intact because the tape actually pulls off pretty decently. I think I can clean it up if I had to.

After I reassembled it I realized I should have taken a pic or two... Hindsight's 20/20.

Anyone else coat their boards? What'd you use?

So I decided to make it water resistant.

I disassembled the control box, separated the circuit board, and laid it on a paper plate. I put a liberal coating of Permatex liquid electrical tape on the component side of the board, being careful not to get any on the two big battery contacts. On the other side I coated the little through-holes and the solder sides of the coil connector and headphone jack. Then I lifted the display from the board just enough to brush the tape under it because there are through-holes there too. The display leads got a decent coating because I wanted the tape to flow around each lead sealing all sides.

Next I coated the areas around the button pads on the faceplate. Just enough to make a seal. Then I used a toothpick to dab and drag some of the tape around the entire faceplate. That sorta made a gasket.

Now the hard part....

I waited the FULL 4 HOURS FOR THE LIQUID TAPE TO DRY before reassembling and powering it up. Then I reassembled the box, mounted it on the stick, connected the coil, crossed my fingers and hit 'Power'.

It works! I air-tested it with my wedding ring, a silver dime, foil, and a nail. Wotks perfect. *WHEW*

I read that some people ran into problems with their circuitry skitzing out when using liquid tape but I think they may have powered it up while the tape was still partially liquid.

Long story short, I took a gamble, voided my warranty, and got lucky.

The warranty may still be intact because the tape actually pulls off pretty decently. I think I can clean it up if I had to.

After I reassembled it I realized I should have taken a pic or two... Hindsight's 20/20.

Anyone else coat their boards? What'd you use?

If I had a water resistant camera I'd make an extreme metal detecting vid, lol!

If I had a water resistant camera I'd make an extreme metal detecting vid, lol!