Yeah... say that fast three times!!

My name is Wayne, I posted for the first time last week on the Sov forum under "New Kid In Town".

In my first post I stated that I had been a metal fabricator for 41 years and a Rockhound for about 30 years.

I have made most of my Rockhound tools that I use from titanium because of the light weight and being stronger than steel. Now that we(wife&I) have planned to return to using metal detectors for beach and relic hunting, I started looking around for the different tools we would need on a hunt. I have made plans to make a few we may need...

the first being a beach scoop.

I no longer work for a fabrication shop that has all the nice CNC equipment to form any shape in metal. I work in the maintenance department of a company and they are limited in metal working tools other than a lathe, mill, and small press. So, my fabrication is very limited to the work I'm able to do. Most of my work is by hand in my basement.

I love to work titanium! Titanium reminds me of myself...light weight... strong for it's weight...don't like to have it's form charged... hard to make look "pretty"... and gets cussed at a lot!

Anyhow(Southern Word!)...

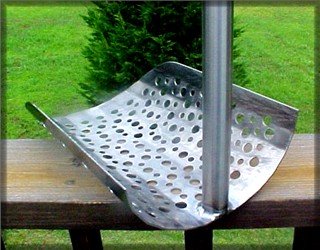

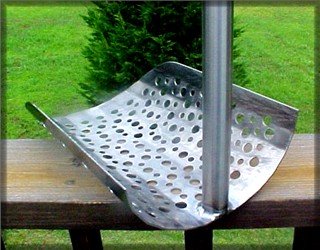

Thought I would show you what's been done on the scoop as of now.

The pan was made from a piece of 6-4 titanium sheet 11"X12" and .071 thick. I made a bottom die and a top die to use in the 40 ton press at work(I work nights when the Boss isn't around!). I made 5 breaks(bends) on both sides of the center two inch section of around 16 degrees each, this made each side roll to almost a vertical total. I drilled 192 holes in the pan after it was formed using my trusty Craftsman China Made $75 Drill Press and several drill bits! The holes are 7/16" and 5/16". The handle is titanium 1" OD 3-2.5 tube that is .051" wall. This tube is 36" long and was bought on eBay along with the sheet. I plan to off-set the handle to the rear at about a 15-20 degree angle about 10" from the bottom of the pan.. I'm still looking to find another piece of sheet to finish the rear of the scoop pan too.

I'll weigh the scoop after it's finished with an accurate scale at my work... because it doesn't move the needle on the bathroom scales much!

The best at ya!!

Wayne

My name is Wayne, I posted for the first time last week on the Sov forum under "New Kid In Town".

In my first post I stated that I had been a metal fabricator for 41 years and a Rockhound for about 30 years.

I have made most of my Rockhound tools that I use from titanium because of the light weight and being stronger than steel. Now that we(wife&I) have planned to return to using metal detectors for beach and relic hunting, I started looking around for the different tools we would need on a hunt. I have made plans to make a few we may need...

the first being a beach scoop.

I no longer work for a fabrication shop that has all the nice CNC equipment to form any shape in metal. I work in the maintenance department of a company and they are limited in metal working tools other than a lathe, mill, and small press. So, my fabrication is very limited to the work I'm able to do. Most of my work is by hand in my basement.

I love to work titanium! Titanium reminds me of myself...light weight... strong for it's weight...don't like to have it's form charged... hard to make look "pretty"... and gets cussed at a lot!

Anyhow(Southern Word!)...

Thought I would show you what's been done on the scoop as of now.

The pan was made from a piece of 6-4 titanium sheet 11"X12" and .071 thick. I made a bottom die and a top die to use in the 40 ton press at work(I work nights when the Boss isn't around!). I made 5 breaks(bends) on both sides of the center two inch section of around 16 degrees each, this made each side roll to almost a vertical total. I drilled 192 holes in the pan after it was formed using my trusty Craftsman China Made $75 Drill Press and several drill bits! The holes are 7/16" and 5/16". The handle is titanium 1" OD 3-2.5 tube that is .051" wall. This tube is 36" long and was bought on eBay along with the sheet. I plan to off-set the handle to the rear at about a 15-20 degree angle about 10" from the bottom of the pan.. I'm still looking to find another piece of sheet to finish the rear of the scoop pan too.

I'll weigh the scoop after it's finished with an accurate scale at my work... because it doesn't move the needle on the bathroom scales much!

The best at ya!!

Wayne