A

Anonymous

Guest

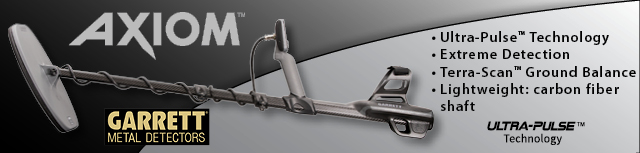

Does anyone have a remedy,cure,fix,suggestion on how to make that wobble where the upper and lower shaft join go away? It drives me crazy and makes this excellent machine seem like a cheap imitation of itself. It just seems to be getting worse as time passes (I bought new about 3-4 years ago). Thanks for any help. Mike